ピックアップ

-

ニュース解説:建築・住宅

台湾地震の現地ルポ、倒壊ビルの図面で分かった耐震性の弱点

-

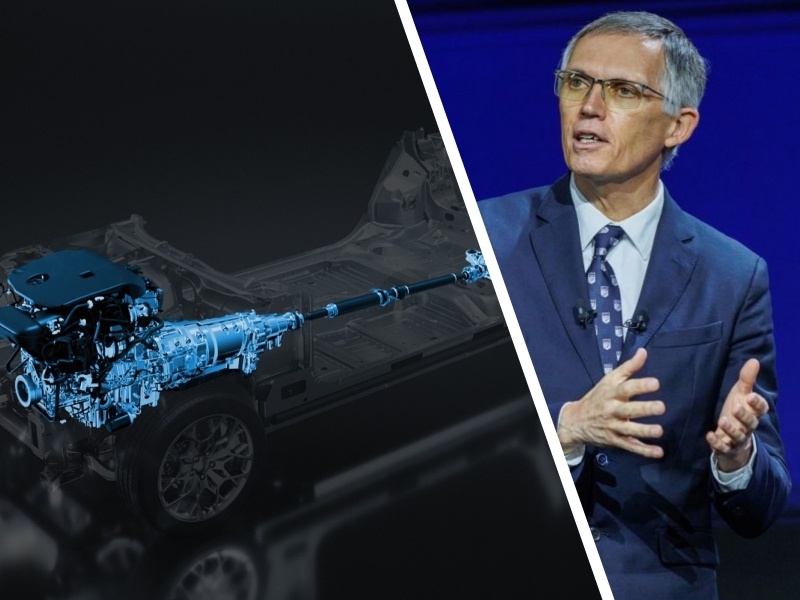

技術トップに聞く

「単独の技術進化だけでは通用しない」、変革に動くアイシン

-

-

動かないコンピュータ

NECが受注したe-Govのガバクラ移行が大幅遅延、構築手法の途中変更が影響か

-

2025年大阪・関西万博

万博現場の爆発事故はメタンガスが原因、溶接作業前に濃度測定せず

-

-

北京モーターショー2024

日産がNEVのコンセプト車4車種を公開、2026年度までに中国に投入

-

トラブルからの脱出

IIJ公式サイトのPVがある日突然13倍に、バズったわけでも炎上したわけでもない裏側

-

-

まち再発見!とことこ散歩

東京・丸の内エリアのポテンシャルを高めた、江戸の運河「道三堀」

-

ニュース解説

ルンバが“4万円切り”、センサー全面見直しで「一家に一台」目指す

-

ニュース

-

日立の2024年3月期決算は減収増益、「生成AIに集中的に投資していく」

日立製作所は2024年4月26日、2024年3月期の連結決算(国際会計基準)を発表した。売上高に当たる売上収益は前の期比11%減の9兆7287億円、調整後営業利益は同1%増の…

-

NECの2024年3月期は10%営業増益、5事業が「低収益」水準から脱却

NECは2024年4月26日、2024年3月期の連結決算(国際会計基準)を発表した。売上高に当たる売上収益は前の期比5%増の3兆4772億円。営業利益は10%増の1880億円…

-

東北大学サイエンスパーク構想が本格始動、共創の場やコミュニティーを三井不と構築

2024年4月26日、東北大学と三井不動産は「東北大学サイエンスパーク構想」の本格始動と進捗を発表した。東北大学の持つ人材や設備などを広く社会に提供し、産学連携でイノベーショ…

トピックス

-

日経クロステック編集部おススメ

ニデックの新経営体制、世界をどう攻めるか

-

情報技術マンスリー・アーカイブス

IT大手2024年春闘/待ったなし!物流2024年問題/みずほ、なるか4度目の正直

-

先端技術マンスリー・アーカイブス

「EV優先」設計でエンジンに逃げ道/難関だらけのEUV露光装置/寒暖差270℃を耐えたSLIM、月面活動に活路

-

建設業界マンスリー・アーカイブス

日本橋の首都高地下化、大成建設が受注/紀の川ICの変状原因は盛り土の透水性低下/監理技術者の専任緩和へ

-

知ったかぶりをする前に読んでおきたい「IT基本用語辞典」

-

仕事に役立つ! IT・電機・製造・建築・土木の用語集&Excel・Linux・ネットワークのコマンド集

-

ぜひお申し込みください「日経クロステック登録会員(無料)」の特典を紹介

-

有料会員は全記事読み放題!見たい記事が必ず探せる「日経クロステック活用ガイド」

特設サイト

日経クロステック/技術メディアの本

-

図解 木造住宅トラブルワースト20+3 「雨漏り事故」「構造事故」の事例から学ぶ原因と対策

木造住宅のトラブルを「雨漏りワースト20」と「構造ワースト3」として類型化。原因と対策と損害額が...

-

東京大改造2030 都心の景色を変える100の巨大プロジェクト

建築や土木の専門記者が取材した、一歩踏み込んだ東京の再開発プロジェクトを豊富な写真や図面で紹介し...

-

一級建築士矩子と考える危ないデザイン

住宅や建築物で起こる身近な事故と背景、効果的な防止策を人気建築漫画「一級建築士矩子の設計思考」の...

-

ソフトバンク もう一つの顔 成長をけん引する課題解決のプロ集団

ソフトバンクにはモバイルキャリア事業以外のもう一つの顔が存在する。本書ではキーパーソンへのインタ...

-

検証 能登半島地震 首都直下・南海トラフ 巨大地震が今起こったら

地震発生直後に現地で撮影した被害写真を多数掲載。専門家や施設関係者への取材から見えてきた建築・土...

-

次世代自動車2024

【4月30日まで早割実施中!】日経Automotiveが、激動する自動車業界の1年を振り返り、今...

注目のイベント

-

日経クロステックNEXT 関西 2024

2024年5月16日(木)~5月17日(金)

-

日経ビジネスCEOカウンシル

2024年5月16日(木)17:00~19:50

-

VUCA時代に勝ち残る戦略的サプライチェーン構築に向けて

2024年 5月 24 日(金) 10:00~16:20

-

人手不足を乗り越える 日本の産業界成長のシナリオ2024

2024年5月30日(木)10:20~17:45

-

キャリア・オーナーシップが社会を変える

2024年6月3日(月)~6月5日(水)

-

DX Insight 2024 Summer

2024年6月4日(火)、5日(水)

-

WOMAN EXPO 2024

2024年6月8日(土)10:00~17:30

-

デジタル立国ジャパン2024

2024年6月10日(月)、11日(火)

-

DIGITAL Foresight 2024 Summer

2024年6月13日(木)~8月8日(木)16:00~17:00 ※毎週火・木曜開催予定

-

成長戦略への次の一手、製品・サービス強化に効くDXの本質(仮)

2024年 6月 14日(金)

注目記事

注目記事

特設サイトアーカイブ

日経クロステック Special

What's New!

IT

- Webサイト運営の新手法「サイト群管理」

- AI活用を加速するストレージの要件は

- 経営の見える化を目指すマイナビの挑戦

- PayPay銀行、新時代の銀行インフラ

- 生成AIとサイバー攻撃/重要な4つの観点

- “新しい働き方”にふさわしいPCとは?

- システム運用を劇的に効率化するには?

- 【生成AI事例】デジタルで現場をDX化

- 「クラウド時代のあるべき運用」を熱く議論

- 業務や役割に応じた「社員に最適なPC」

- 生成AI活用へ「待ったなし」成功の秘訣

- 目指すは相互に行き来できるマルチクラウド

- 「稼ぐ力」を劇的に高めるROIC経営

- 大企業にもキントーンの導入が進む理由

- 医療セキュリティ対策の鍵はSaaS化?

- 「サーバ―」部門満足度トップ企業に訊く

- 製造業DX「データドリブン経営成功のシナリオとは」

- NTTドコモ支援の実践型教育プログラム

- 大教大とマウスパソコン教室の在り方を研究

- ジェイテクトエレクトロニクスのDX事例

- 欧州トップ企業語る日本のセキュリティー

- ビジネスPC、ITデバイス購買DXを推進

- 生成AIの活用の鍵は「内製とアジャイル」

- AIと自動化でエンジニアの能力を解き放て

- NTTデータに優秀なデジタル人財が集まる理由

- ゼロトラスト成功の秘訣を神田れいみと探る

- 神田れいみと学ぶ「ネットワーク活用白書」

- 専門家が斬る日本の意識と対策の現状は?

- オリックス銀行×富士通時田社長 特別鼎談

- マネージドサービスが安価に利用できる理由

- 脱レガシー案件≫SIerに必要な人財像は

- DXや生成AI活用に挑む大阪府

- 3段階で考える、DXで企業力を高める方法

- イノベーションの起爆剤

- 大規模プロジェクトでPMが注意すべき点は

- 守りながら攻める“製造DX”の方法論とは

- ランサムウエアから診療データはこう守る

- 最新サーバーに学ぶ熱設計の最前線

- PC管理の課題を課題をまるごと解決

- 日本語に強い「和製生成AIモデル」が誕生

- 動画解説>生成AIからDX変革まで

- 大阪・名古屋エリアのDXが注目される理由

- 最適なネットワークを早く安く簡単に実現!

- セキュリティ×スキルUP≫JSOLの提案

- 力点は「未来予測」へ:データ利活用の勘所

- 生成AI活用でSAP BTPの価値が進化

- ServiceNowでDXを加速≫方法は

- SAPプロジェクトの全体像をいかに描くか

- 先端教育の現場で活躍する大学副学長が使い続けるレッツノート

- DX時代、IT人財/組織の“理想像”は?